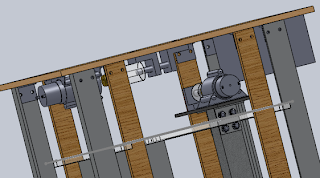

We revised the solid model of our machine, including three motors (one on the top plate, one on the MCM and one on the bottom to drive car). We may need to buy another 24" long Al stock to build the car frame edges since the one in the kit is only 18" long so we cannot hold both scoop and sweeping arm inside of the car when drive it across the table.

Instead of making the platform moving with side wheels in the slot, we decide to make this simpler. We now have the platform with four little extrudes which slide between the car frame and the wood support.It will be easier to build and the function is still the same.

We inserted our control box on the top right corner since we have extra space there and it will not interfere with other modules.

We are going to use the double gear box to drive our car, instead of mounting it horizontally, we will build it vertically on a side wall since the space is limited and dont want the platform interfere with it which may not let the scoop and sweeping arm go down further.

The total dimension for our machine (maximum in each side) is

12.00 " (L) *11.05 " (W)*23.29 " (H).It meets the dimension requirement so far.

| We are going to finish manufacturing rest of our MCM, bill of materials and step by step manufacturing plan by next Wednesday for MS 8.For the MCM, we are going to use waterjet to cut the Al sheet and made several pillow blocks (L shapes) to let the shafts go through. |

No comments:

Post a Comment